Lister Engine Serial Numbers

Identifying Lister Diesels An article from the Stationary Engine Newsgroup July 1998 This one is for Dene Oehme in Australia, who asked if I could put together a bit on identifying Lister diesel engines for his new web pages (which are a very good effort) There have been quite a few newcomers to the NG who have asked me if I could explain how to differentiate between various models of the Lister Diesel engines. I have not had that problem myself, as I tended to get right in amongst them from day one, and also spent a lot of time going through handbooks and manuals that I picked up at autojumbles etc. For the complete beginner, references to CS, CD,CE, JP, 61/6, etc etc are all a bit confusing at first, but if taken in historical order there is some logic behind the designations.

JP, JS and JK Engines. The first diesel was the 9/1 (nine horsepower, one cylinder) 1000 rpm engine, which also became known as the JP. The JP came from the Joint Product agreement between Lister and Ruston & Hornsby, whereby they apparently agreed to keep to their own engine size ranges and not compete against each other. This left Listers with engines below 100HP, while R&H handled sizes above that. The block was integral with the crankcase on all models, and wet liners were used. The one feature that characterised the JP, CS, CD/CE and FR engines was the compression change-over valve.

Lister Petter - Engine production dates Lister Engines. A 1909 – 1962. AK 1909 – 1962. Lister-Petter Engines. CR3 1986 – 1995. CRK3 1986 – 1995. 55 rows Home / Lister Petter Engine Data / Lister Petter Production Dates. Printable version.

This device made starting from cold without an external heat source a much more reliable process, and earned Lister a big market both in the UK and overseas. The valve operates by putting a small ante-chamber in the head in communication with the main combustion chamber or not. When the chamber was in communication, the compression ratio was lowered, and this was the running configuration. When the chamber was taken out of communication, the compression ration was raised, and this was the starting configuration.

For operation at very high altitudes, the change-over valve could be left in the starting position. Lubrication was by wet or dry sump gear pressure pump.

Saxophone.org - created by saxophone players for saxophone players. Features an active saxophone forum, buy sell trade your sax, saxophone museum, sax teachers and more. Join the jazz saxophonists who have rediscovered the sound of the legendary Mark VI, and have made the Selmer 72 Reference 54 alto saxophone their horn of choice. The Reference 54 alto takes its inspiration from a 1958 mid-70,000 serial number Mark VI. Serial Number Ranges By Model • Full Serial Number Chart; Selmer Serial Number Ranges By Model. Although, as the chart below illustrates, the Mark VI was produced until (roughly) serial #378000, this applies only to the Sopranino model. Selmer reference 54 serial numbers. Selmer serial numbers? 14,999 Selmer list ends. Reference 2000-2001 -,999. De Saxophoonwinkel with serial # 599,xxx. I have a Reference 54 Tenor that.

The JP was never called a JP until later on in it's life, and the single was always called the 9/1, not a JP1. Later versions in two, three, four and six cylinders were variously called the 18/2 (later 21/2) JP2, 30-3 (JP3), 40-4 (JP4) and 61-6 (JP6) The JS was a short-lived variant of the JP, and I understand was only made in a three-cylinder version, the JS3. Problems with centre bearings caused a lot of trouble for Lister. The JK was the final variant, with no compression change-over valve, pressure lubricated valve gear, higher speed range up to 1500 RPM and copper-lead bearings.

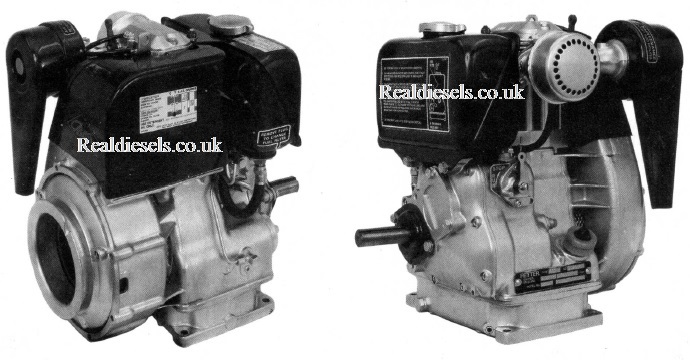

The JP, JS and JK engines all had rocker-box mounted decompressor handles and a single flywheel at the opposite end to the fuel pump. The JS3 and JK4 shared a non-standard water circulating pump. A few options such as power take-off and air-starting equipment were pretty common, and there were numerous marine versions with different configurations altogether to the industrial units we are used to. A lot of parts are common to all three engine ranges, but be careful over the heads, bearings and con-rods. CS Cold-Start Diesels The cold-start range of diesels came out after the 9/1, and were intended for low-speed farm implement type applications, and the first engines were the 5/1 models (five horsepower, one cylinder) producing 5HP at 600 rpm.

This early engine had many of the contemporary Lister 'L' engine parts in common, such as crankcase, crank, bearings etc. The CS label was given to the engine by Listers, and it was incorporated on the spec plates as part of the engine serial number. Whether this was done officially at first is not known, but the factory eventually followed suit. The CS range always had twin flywheels (except for Hamworthy Distarto ships compressor engines which had one) and the early ones were spoked. Later engines and Start-O-Matic generating engines had solid disc flywheels of two of three different versions. The other main difference between the CS range and all the others is the use of a separate cylinder block which was detachable from the crankcase (twin blocks on the 10/2 and 12/2) The 5/1 was upgraded to the 6/1 by a speed increase to 650 rpm, and there was also a 3/1 version, upgraded to 3½/1, which was never that popular, and is somewhat collectible today. The later 8/1 was a much-modified engine, with no compression change-over and different injector and pump.

Basic bottom end remained much the same for all versions of the singles, while the twins were obviously different again. Later 8/1's had aluminium rocker covers, early engines had holes in the cover for the injector 'feeler' pip on top of the injector. Early 5/1 engines had 1.75' diameter crankshafts, later had 2'. You cannot fit undersized mains to any of the CS engines, as they were not made. (Think about it - the mains are inboard of a shaft that will not be undersized, and the bearings are one-piece tubular type) So if you screwed up a crank, you had to have a new one. Nowadays you can get cranks metal sprayed and re-ground to full size.